Invento Silver Line S400 – Wheel aligner 3D with autotracking

Purpose and Application:

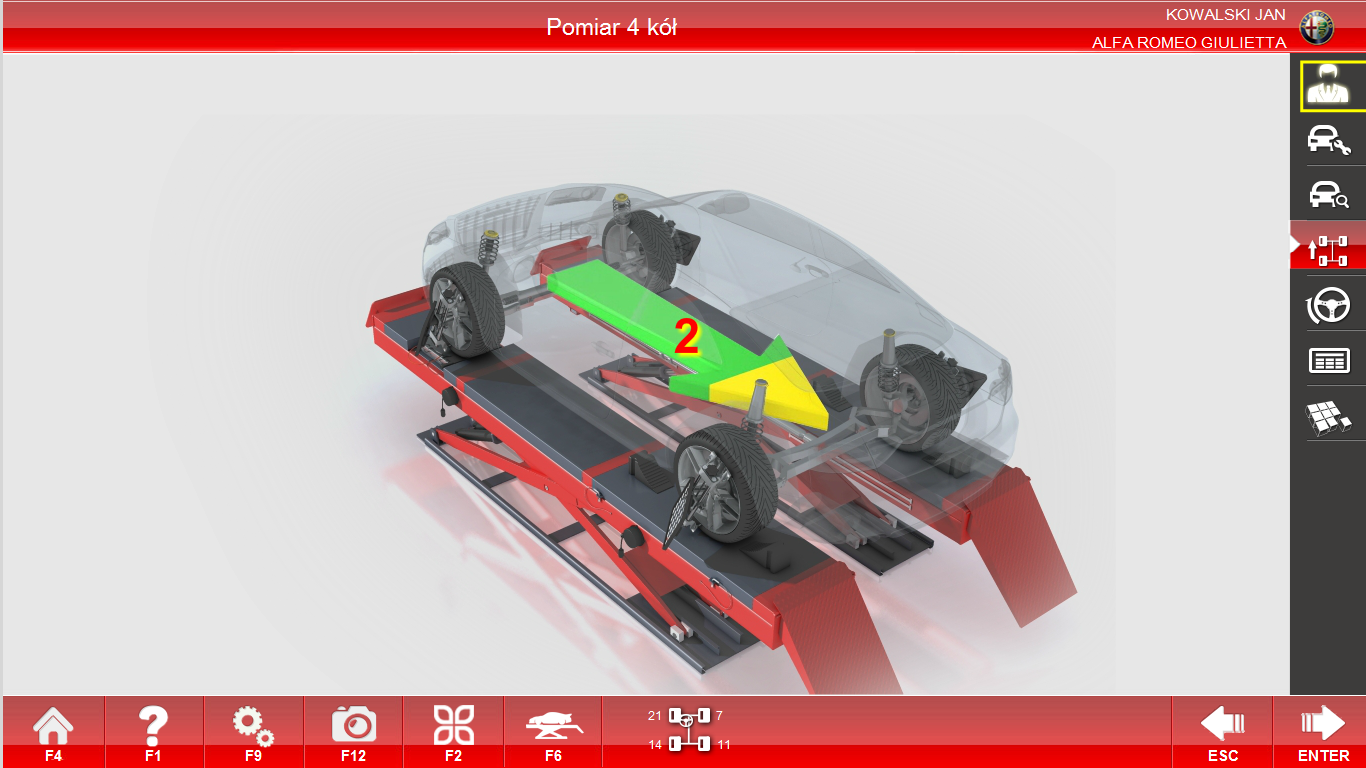

The Invento S400 is an advanced device from the Invento Silver series, primarily designed for use with scissor lifts or four-column lifts. With automatic camera adjustment, the device works seamlessly with lifts, ensuring smooth and comfortable operation.

Advanced 3D Technology:

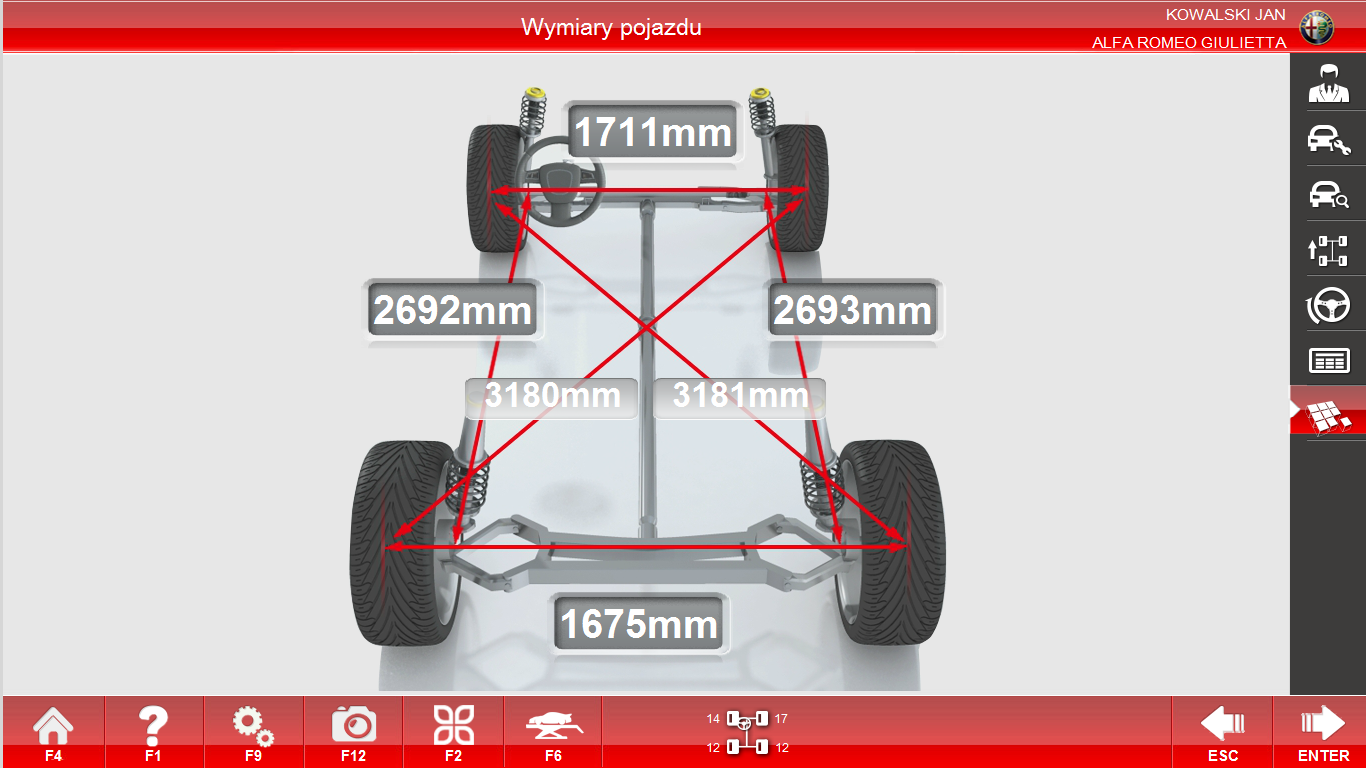

The 3D technology used in the Invento S400 guarantees fast and accurate vehicle geometry measurement. It is significantly more precise and faster than traditional infrared (CCD) technologies. With high-resolution cameras, the device continuously monitors the positioning of reflectors and provides accurate and up-to-date results.

AutoData Database:

The device utilizes the AutoData database, which contains adjustment point diagrams, simplifying daily work and enhancing measurement process efficiency.

Automatic Camera Height Adjustment:

The cameras are equipped with auto-tracking functionality, which allows for automatic tracking of reflector positions and adjustment to the vehicle’s height changes. This ensures a smooth and hassle-free measurement and adjustment process.

Passive Reflectors:

Special plastic cameras/reflectors eliminate the need for electrical devices on the wheels, cables, and signals between the heads and the device. This provides ease of use and minimizes costly repairs or calibrations.

Vehicle Status Report:

The vehicle status protocol feature enables the creation of a report when the vehicle is brought into the workshop. This report contains information about tire condition, suspension wear, and other critical components.

Adjustment with Raised Suspension:

The program allows the measurement results to be “frozen” while the vehicle is lifted, which is especially useful when adjustments require raising the vehicle.

Adjustment Without a Wheel:

This feature allows for angle adjustments with the wheel removed, making it easier to work on hard-to-reach suspensions. Special adapters (optional) are required for this function.

Cart/Skid and Alignment Adjustment with Turned Wheels:

Special procedures simplify the cart adjustment under the engine and alignment adjustments in vehicles with an adjustment rod in the upper suspension.

4-Point Wheel Clamps:

Convenient and easy-to-use 4-point clamps with a wide range (10”-24”) enable quick and efficient work, allowing for wheel wobble compensation by rolling the vehicle.

Fast and Efficient Work:

Wobble compensation and alignment and camber measurements are carried out during vehicle rolling, with a movement distance of less than 20 cm. This saves time and space, eliminating the need to lift the car.

Standard Equipment:

• 4 reflectors (heads)

• 4 head holders (10-24″, 4-point)

• PC

• Keyboard and mouse

• LCD panoramic monitor

• Color printer

• Steering wheel and brake lock

• Rotary tables

• Geometry system: 3D

• Number of cameras: 2

• Alignment range: ± 20º

• Camber range: ± 10º

• Kingpin inclination range: ± 20º

• Power supply: 230V, 50Hz

• Head holder size: 10 – 24”

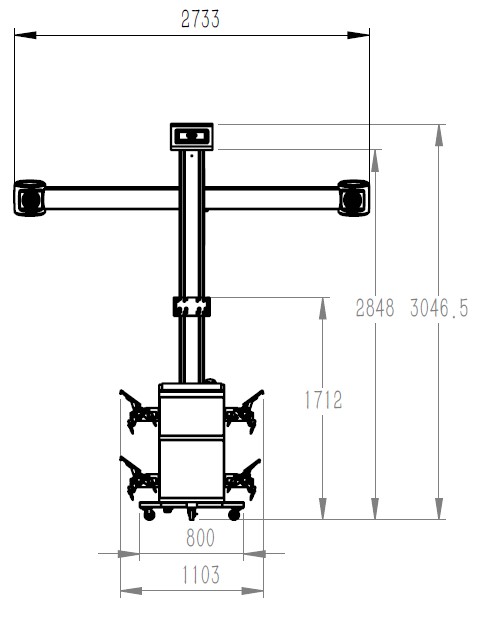

• Dimensions (H x W x D): 3046 x 2733 x 835 mm

Gwarancja 12 miesięcy

- Producent / Podmiot odpowiedzialny:

- TIPTOPOL SP. Z O.O.

ul. Kostrzyńska 33

62-010 Pobiedziska

Polska

sklep@tiptopol.pl

+48618152200